LAN cable color coding ensures consistent and reliable network connections by organizing wires according to standardized schemes like T568A and T568B, minimizing errors and improving maintainability․

1․1 Importance of Color Coding in Network Wiring

Color coding in LAN cables ensures consistent and error-free network installations by standardizing wire connections․ It simplifies troubleshooting, reduces human error, and enhances maintainability․ By adhering to T568A and T568B standards, technicians can quickly identify wire pairs, ensuring reliable data transmission․ Proper color coding also supports scalability and organization in complex network setups, making it a foundational best practice for efficient networking․

1․2 Brief Overview of T568A and T568B Standards

T568A and T568B are EIA/TIA standards for Ethernet cable wiring, defining specific pinout configurations․ T568A pairs green and white/green wires, while T568B pairs orange and white/orange wires․ Both standards ensure compatibility with network devices, with T568B being more commonly used in modern setups․ These standards guide the arrangement of wire pairs in RJ45 connectors, ensuring reliable data transmission and minimizing connectivity issues․

Understanding T568A Color Coding Standard

The T568A standard provides a specific color coding scheme for wiring Ethernet cables, ensuring consistent connections and minimizing errors in network setups and installations․

2;1 Wire Pair Colors and Their Designations

The T568A standard assigns specific colors to wire pairs for clear identification․ The pairs are color-coded as follows: White/Green, Green, White/Orange, Blue, White/Blue, Orange, and a spare pair․ These designations ensure consistent wiring, reducing errors and improving network reliability․ The color scheme helps technicians quickly identify and connect wires during cable installation and troubleshooting․

2․2 Pinout Diagram for T568A Standard

The T568A pinout diagram details the arrangement of wires within an RJ-45 connector․ Pins 1-8 correspond to specific wire colors: White/Green (Pin 1), Green (Pin 2), White/Orange (Pin 3), Blue (Pin 4), White/Blue (Pin 5), Orange (Pin 6), White/Brown (Pin 7), and Brown (Pin 8)․ This configuration is essential for creating straight-through cables, ensuring proper data transmission across networks․

2․3 Application of T568A in Straight-Through Cables

The T568A standard is widely used for straight-through cables, connecting devices like PCs to switches or routers․ Both ends follow the same pinout, ensuring compatibility and proper data transmission․ This consistency is critical for network performance and reliability, making T568A a preferred choice for most Ethernet connections in residential and commercial settings․

Understanding T568B Color Coding Standard

The T568B standard is another widely used wiring scheme, differing from T568A by swapping green and orange pairs․ It’s commonly used in modern networks and supports PoE, ensuring reliable connections․ Both standards comply with EIA/TIA-568, maintaining network performance and consistency․

3․1 Differences Between T568A and T568B

The primary difference between T568A and T568B is the swapping of the green and orange wire pairs․ T568A assigns green to pins 1-2 and orange to 3-6, while T568B reverses this, placing orange on 1-2 and green on 3-6․ Both standards maintain compatibility with network devices but differ in wire arrangement, ensuring proper data transmission when applied consistently in network setups․

3․2 Wire Pair Colors and Their Designations

In the T568B standard, the wire pairs are designated as follows: orange for pair 1, orange-white for pair 2, green for pair 3, green-white for pair 4, blue for pair 5, blue-white for pair 6, brown for pair 7, and brown-white for pair 8․ These color codes ensure proper identification and consistent wiring, critical for maintaining reliable data transmission and network performance across all connections․

3․3 Pinout Diagram for T568B Standard

The T568B pinout diagram assigns the following colors to each pin: Pin 1 ⸺ White/Orange, Pin 2 ⎼ Orange, Pin 3 ⸺ White/Green, Pin 4 ⎼ Blue, Pin 5 ⸺ White/Blue, Pin 6 ⎼ Green, Pin 7 ⸺ White/Brown, and Pin 8 ⸺ Brown․ This arrangement ensures consistent wiring and proper data transmission, with the orange and green pairs swapped compared to T568A, making it interchangeable in most modern network devices for reliable connectivity․

3․4 Application of T568B in Straight-Through Cables

The T568B standard is widely used for straight-through cables, connecting devices like PCs to switches or routers․ It ensures consistency in wiring, supporting Category 5e, 6, and 7 cables․ The color-coded pairs maintain proper signal transmission, reducing errors and ensuring reliable network performance across various Ethernet applications․

Crossover Cable Color Coding

Crossover cables reverse wire pairs at one end, enabling direct connections between similar devices (e․g․, PC-to-PC)․ They use T568A on one end and T568B on the other․

4․1 When to Use Crossover Cables

Crossover cables are used to connect two identical devices directly, such as PC-to-PC or switch-to-switch, without a hub․ They enable peer-to-peer communication, ideal for temporary connections or small networks, ensuring proper signal crossover between transmit and receive pairs for reliable data transmission․

4․2 Color Coding for Crossover Cable Wiring

Crossover cables use a specific color coding where the green and orange wire pairs are swapped compared to straight-through cables․ This ensures proper data transmission between identical devices․ The T568A standard swaps the green and orange pairs, while T568B maintains consistency by reversing these pairs at one end․ This wiring ensures reliable communication in peer-to-peer connections without the need for a hub or switch․

4․3 Differences Between Straight-Through and Crossover Cables

Straight-through cables connect devices of different types (e․g․, PC to switch) using identical wiring at both ends, while crossover cables connect similar devices (e․g․, PC to PC) by swapping the green and orange wire pairs․ This swap allows proper data transmission in direct connections․ Straight-through cables follow T568A or T568B standards uniformly, whereas crossover cables reverse these pairs at one end to enable peer-to-peer communication without a hub or switch․

Tools Required for LAN Cable Wiring

Essential tools for LAN cable wiring include cable strippers, crimping tools, and RJ45 connectors․ Cable testing tools ensure proper connections and verify cable integrity efficiently․

5․1 Cable Strippers and Crimping Tools

Cable strippers are essential for removing the outer jacket of LAN cables, exposing the inner wires․ Crimping tools are used to securely attach RJ45 connectors to the cable ends․ These tools ensure precise wire trimming and proper connector seating, preventing damage and ensuring reliable connections․ Regular maintenance of these tools is crucial for consistent results and long-term network performance․

5․2 RJ45 Connectors and Their Compatibility

RJ45 connectors are designed to terminate LAN cables, ensuring secure connections to network devices․ Compatibility with cable categories (e․g․, Cat5e, Cat6, Cat7) is crucial for optimal performance․ Proper installation of RJ45 connectors prevents signal loss and ensures reliable data transmission․ Using high-quality connectors and crimping tools guarantees consistent network performance and minimizes connectivity issues․

5․3 Cable Testing Tools for Verification

Cable testing tools are essential for verifying the integrity of LAN cables after wiring․ Tools like cable testers, multimeters, and network cable testers help ensure proper connections and detect faults․ These tools check for continuity, short circuits, and wiring accuracy․ Using them ensures cables meet industry standards and prevents connectivity issues․ Advanced testers also support higher-category cables like Cat6 and Cat7, ensuring reliable network performance․

Step-by-Step Guide to Wiring LAN Cables

Strip the jacket, untwist pairs, arrange wires per T568A/B, trim, and crimp RJ45 connectors․ Verify with testing tools for proper connectivity and performance․

6․1 Stripping the Cable Jacket

Use a cable stripper to remove 2 inches of the outer jacket․ Carefully strip without damaging the inner wires, ensuring clean access for wiring․

6․2 Untwisting and Arranging Wire Pairs

Carefully untwist the wire pairs and straighten them out․ Identify each pair by their distinct colors, ensuring proper alignment according to the chosen standard (T568A or T568B)․ Arrange the wires in the correct sequence, maintaining consistency to avoid connection issues․ Use a cable management tool if needed to hold the wires in place during the process․

6․3 Trimming and Crimping the Wires

Trim each wire to approximately 0․5 inches in length, ensuring they are even and aligned properly․ Use a crimping tool to securely attach the RJ45 connector, applying firm pressure to ensure the wires are held in place․ Verify the connection by gently tugging on the cable to confirm it is properly crimped and will not come loose during use․

6․4 Testing the Wired Cable

After wiring, use a cable tester to verify all connections are correct and functioning properly․ Ensure continuity by checking each wire pair and confirming no short circuits or open connections․ Test both ends of the cable to guarantee reliable data transmission․ A properly tested cable ensures optimal network performance and minimizes potential connectivity issues․

Best Practices for Cable Management

Label cables clearly, organize them neatly, and use color coding to differentiate network types․ Maintain consistency in wiring to ensure efficiency and a visually clean setup․

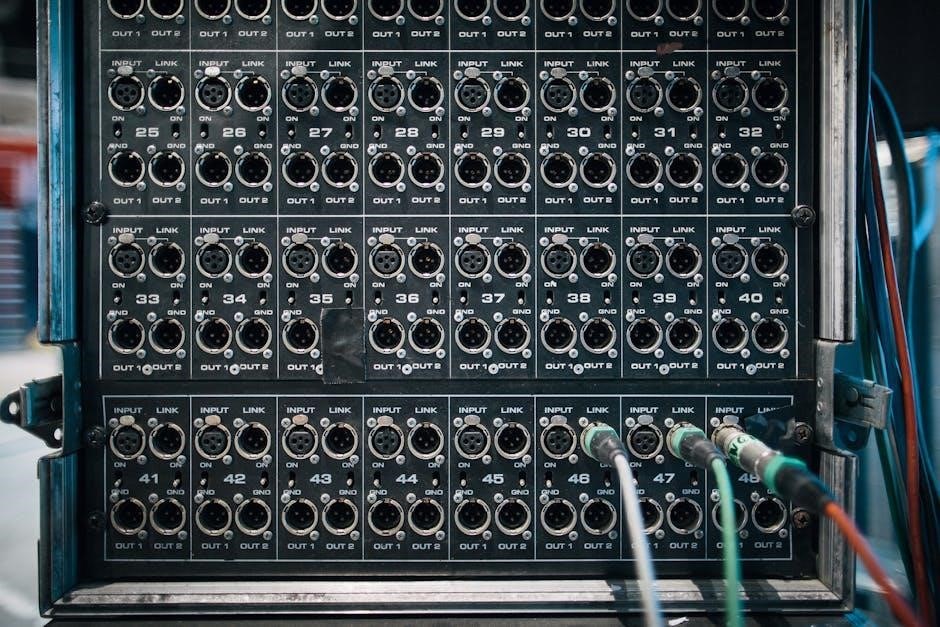

7․1 Labeling and Organizing Cables

Labeling and organizing cables is crucial for efficient network management․ Use color coding to differentiate network types, such as yellow for PoE or green for management․ Label both ends of each cable with its purpose and destination․ Organize cables using patch panels, cable ties, and cable management racks to maintain a tidy and accessible setup, reducing downtime during troubleshooting or upgrades․

7․2 Using Color Coding for Different Networks

Color coding is essential for distinguishing between different networks․ Assign specific colors to various network segments, such as red for critical systems or blue for guest networks․ This practice enhances visibility, reduces errors, and simplifies maintenance․ Consistent color schemes across cables and connectors ensure seamless identification, improving overall network organization and troubleshooting efficiency․

7․3 Maintaining Consistency in Wiring

Maintaining consistency in wiring is crucial for network reliability and ease of maintenance․ Always adhere to standardized wiring schemes, such as T568A or T568B, and use compatible tools for precise connections․ Proper labeling and documentation ensure easy identification and troubleshooting․ Regular audits and team training further enforce consistency, preventing errors and connectivity issues while simplifying future network upgrades․

Troubleshooting Common Wiring Issues

Identify wiring errors like incorrect pinouts or reversed pairs․ Use cable testers to verify connections and detect faults․ Visual inspections and diagnostic tools help resolve connectivity problems efficiently․

8․1 Identifying Wiring Errors

Common wiring errors include incorrect pinouts, reversed wire pairs, or open/short circuits․ Use cable testers to detect mismatches in connections․ Visual inspections can reveal damaged or misaligned wires․ Ensure compliance with T568A or T568B standards to avoid errors․ Faulty crimps or improper stripping can also cause connectivity issues, requiring retermination or replacement of faulty segments․

8․2 Resolving Connectivity Problems

Resolving connectivity issues often starts with identifying incorrect cable types, such as using a straight-through instead of a crossover․ Testing with a cable tester reveals wiring faults like open circuits or shorts․ Re-terminating the cable following T568A/B standards ensures proper connections․ Checking network settings like IP addresses and VLANs is crucial․ For PoE issues, a PoE tester can diagnose power problems․ Consistent color coding application maintains network reliability and prevents future issues․

8․3 Verifying Cable Integrity

Verifying cable integrity involves testing wire continuity, insulation resistance, and signal quality․ Use a cable tester to ensure all pins are correctly connected and no wires are shorted or open․ For PoE cables, test power delivery․ Visual inspections can detect physical damage or improper wiring․ Testing tools like multimeters and cable testers are essential for ensuring compliance with T568A/B standards and maintaining reliable network performance․

Practical Applications of LAN Cable Color Coding

LAN cable color coding is widely used in residential, commercial, and industrial networks for organized setups, ensuring reliability and ease of troubleshooting, while supporting PoE and VLAN configurations․

9․1 Residential and Commercial Networking

LAN cable color coding simplifies network installations in homes and offices by ensuring consistent wiring․ It aids in organizing cables, reducing errors, and streamlining troubleshooting․ Commercial settings benefit from standardized setups, while residential applications enjoy seamless connectivity for devices․ Color coding also supports scalability, allowing businesses to expand networks efficiently and maintain reliability across all connections․

9․2 Industrial and Enterprise Networking

In industrial and enterprise environments, LAN cable color coding is crucial for managing large-scale networks․ It ensures uniformity across extensive installations, simplifies maintenance, and reduces downtime․ Enterprises utilize color coding to differentiate network segments, such as VLANs, enhancing organization and security․ This standardized approach supports high-performance connectivity, enabling industrial systems to operate efficiently and reliably in demanding conditions․

9․4 Custom Networking Solutions

LAN cable color coding is a cornerstone in custom networking solutions, enabling tailored designs for specific applications․ It allows for easy identification of cable purposes, enhancing organization and maintenance․ Custom solutions often require unique configurations, and color coding supports these needs by providing clear visual cues; This approach ensures compatibility with specialized connections, such as VLANs or high-speed links, while maintaining scalability and adaptability for complex network demands․

Advanced Topics in LAN Cable Wiring

Advanced LAN wiring incorporates Power over Ethernet (PoE), VLAN segmentation, and future-proofing strategies, utilizing color coding for efficient cable management and network scalability․

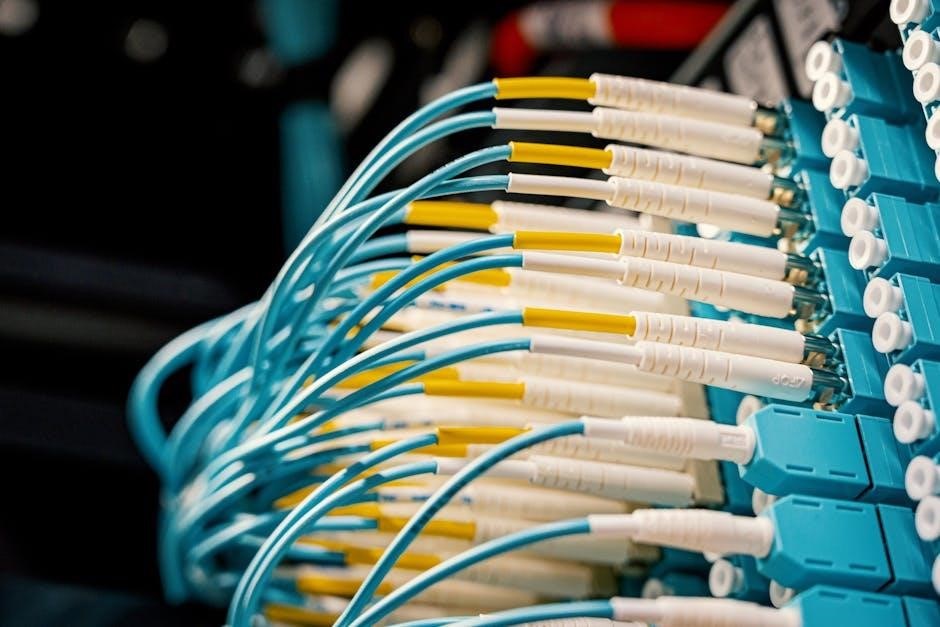

10․1 Power Over Ethernet (PoE) Wiring

Power Over Ethernet (PoE) wiring uses color coding to identify power-carrying wires, ensuring safe and efficient delivery of electricity alongside data transmission․ Yellow cables are often reserved for PoE connections, as per IEEE 802․3af standards, to distinguish them from data-only lines․ This enhances visibility and prevents accidental disconnections, while maintaining network reliability and scalability in powered devices․

10․2 VLAN and Network Segmentation

VLANs (Virtual Local Area Networks) and network segmentation enhance security by isolating traffic․ Color coding plays a role by assigning specific colors to cables serving different VLANs, such as red for management networks and blue for DMZs․ This visual system simplifies network organization, reduces errors, and ensures compliance with security policies, making it easier to manage and troubleshoot large, complex networks effectively while maintaining performance․

10․3 Future-Proofing Your Network

Future-proofing your network involves using scalable infrastructure, such as higher-category cables (e․g․, Cat6 or Cat7), to support future bandwidth demands․ Color coding aids in identifying cables for upgrades or expansions, ensuring consistency․ Modular patch panels and standardized wiring practices, like T568A/B, simplify scalability․ Regular network audits and documentation also help maintain efficiency as demands evolve, ensuring your network remains adaptable and resilient for years to come․

Resources for Further Learning

Recommended PDF guides, online tutorials, and manufacturer specifications provide detailed insights into LAN cable color coding standards, wiring diagrams, and troubleshooting tips for advanced learning․

11․1 Recommended PDF Guides

Comprehensive PDF guides on LAN cable color coding provide detailed wiring diagrams, standards like T568A and T568B, and practical applications․ These resources are ideal for network administrators and learners, offering step-by-step instructions and troubleshooting tips․ Manufacturer-specific guides also ensure compatibility and adherence to industry best practices, making them invaluable for both professionals and those new to network wiring․

11․2 Online Tutorials and Videos

Online tutorials and videos offer step-by-step guides for understanding LAN cable color coding, covering T568A and T568B standards․ These resources provide visual demonstrations of wiring processes, cable testing, and troubleshooting․ Ideal for both beginners and professionals, they include detailed diagrams and practical examples․ Many tutorials are available on platforms like YouTube and technical websites, making learning accessible and self-paced for anyone seeking to master network wiring skills․

11․3 Manufacturer Specifications

Manufacturer specifications provide detailed guidelines for LAN cable color coding, ensuring compliance with industry standards like T568A and T568B․ These documents, often available as PDFs, include wiring diagrams, color codes, and compatibility information․ They are essential for network administrators to verify cable authenticity and ensure proper installation․ Leading manufacturers like GearIT offer comprehensive resources to help users achieve optimal network performance and avoid common wiring errors․

Proper LAN cable color coding ensures reliable network connections, reduces errors, and simplifies troubleshooting․ Adhering to standards like T568A and T568B guarantees consistency and efficiency in network setups․

12․1 Summary of Key Takeaways

LAN cable color coding is essential for consistent and error-free network connections․ Standards like T568A and T568B provide clear guidelines for wiring, ensuring reliability․ Proper tools, such as cable strippers and crimpers, are vital for accurate wire preparation․ Labeling and organizing cables enhance manageability, while adhering to best practices minimizes connectivity issues and ensures efficient network performance․ Understanding these principles is crucial for both residential and enterprise networking environments․

12․2 Final Thoughts on Best Practices

Consistency and organization are key to effective LAN cable management․ Always use standardized color coding for clarity and reliability․ Regularly test cables post-installation to ensure functionality․ Adhere to T568A or T568B standards for uniformity․ Invest in quality tools for precise wire preparation; Label and organize cables meticulously to simplify maintenance․ Use color coding to differentiate network types, enhancing traceability․ Future-proof your network by installing high-speed cables, and maintain consistency across all setups to minimize connectivity issues․