Go-Ferm is a natural yeast rehydration nutrient containing essential vitamins and minerals. It enhances fermentation kinetics, prevents issues, and supports yeast health during winemaking and meadmaking processes.

1.1 What is Go-Ferm?

Go-Ferm is a natural yeast rehydration nutrient designed to enhance fermentation performance. It provides essential vitamins, minerals, and micronutrients to yeast during rehydration, improving survival and activity. Unlike other nutrients, Go-Ferm is specifically formulated to be added to the rehydration water before yeast inoculation, ensuring optimal nutrient uptake. This approach helps prevent fermentation issues, especially under challenging conditions like high sugar or alcohol levels. Go-Ferm is a key tool for winemakers and meadmakers seeking reliable and efficient fermentation processes.

1.2 The Role of Go-Ferm in Fermentation

Go-Ferm plays a crucial role in fermentation by providing yeast with essential nutrients during rehydration. It enhances yeast survival and activity, particularly under challenging conditions such as high sugar levels or alcohol content. By supplying bio-available micronutrients, Go-Ferm helps yeast withstand stress, ensuring a strong and steady fermentation process. This nutrient regimen is vital for maintaining fermentation efficiency and preventing stuck or sluggish fermentations, making it an indispensable tool for winemakers and meadmakers seeking consistent and reliable results.

Importance of Using Go-Ferm

Go-Ferm is essential for enhancing yeast health and ensuring vigorous fermentations, especially under challenging conditions. It provides critical nutrients, preventing stuck fermentations and promoting efficient sugar conversion, resulting in better outcomes.

2.1 Why Use Go-Ferm in Winemaking and Meadmaking?

Go-Ferm is crucial in winemaking and meadmaking as it provides essential micronutrients to yeast during rehydration, enhancing fermentation efficiency and reducing risks of stuck or sluggish fermentations. By supplying vitamins, minerals, and sterols, it supports yeast health, especially under high sugar or alcohol conditions. This promotes vigorous fermentation and improves the overall quality of the final product, making Go-Ferm a vital tool for achieving consistent and successful fermentation outcomes in both wines and meads.

2.2 Benefits for Yeast Health and Fermentation Efficiency

Go-Ferm significantly enhances yeast health by providing bio-available micronutrients, sterols, and fatty acids during rehydration. These nutrients protect yeast from ethanol toxicity and ensure optimal nutrient uptake, leading to stronger, more resilient cells. This results in faster fermentation starts, reduced risk of stuck fermentations, and improved overall efficiency. By addressing nutritional deficiencies early, Go-Ferm supports robust yeast activity, ensuring smoother and more reliable fermentation processes in both winemaking and meadmaking.

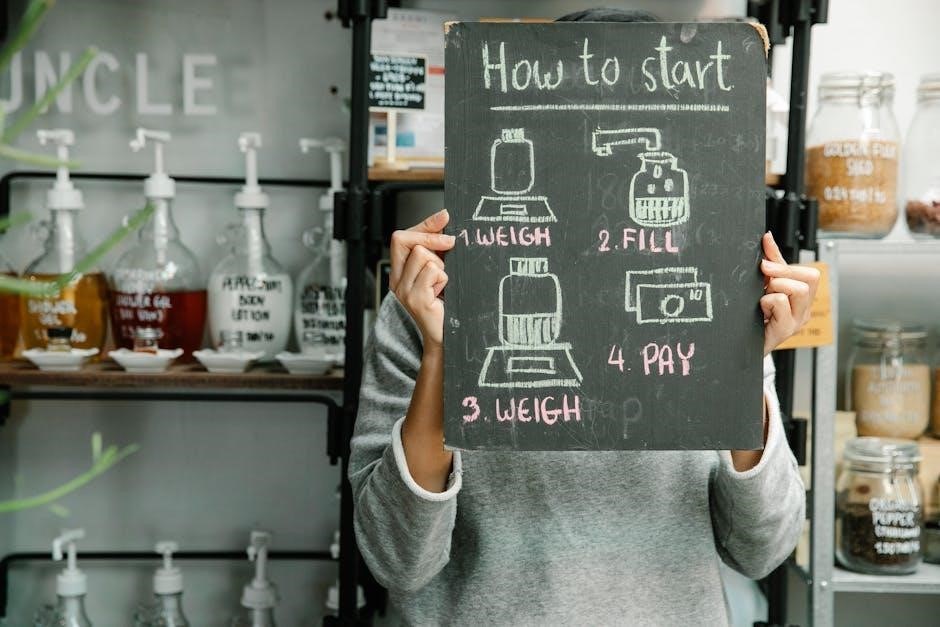

Step-by-Step Instructions for Using Go-Ferm

Mix Go-Ferm in hot water, let cool, add yeast, and acclimate to must gradually for optimal rehydration and fermentation performance in winemaking and meadmaking processes.

3.1 Preparing the Rehydration Solution

Start by mixing Go-Ferm in clean, filtered water heated to 110°F (43°C). Use 20 times the weight of Go-Ferm in water, ensuring proper dissolution. Allow the mixture to cool to 104°F (40°C) before adding yeast. This step ensures optimal nutrient availability and yeast viability, promoting healthy fermentation. Proper preparation is crucial for effective rehydration and preventing fermentation issues.

3.2 Mixing Go-Ferm with Water

Mix Go-Ferm in clean, filtered water at a ratio of 1 part Go-Ferm to 20 parts water by weight. Heat the water to 110°F (43°C) and gently stir until the nutrient dissolves. Avoid over-stirring, as this can introduce oxygen unnecessarily. The mixture should be smooth, with no visible residue. Proper dissolution ensures the yeast receives all necessary nutrients during rehydration. This step is critical for optimizing yeast health and fermentation efficiency. Use 17ml of water for every gram of yeast to maintain the recommended ratio.

3.3 Cooling the Mixture

After mixing, allow the Go-Ferm solution to cool to 40°C (104°F). This ensures the yeast isn’t exposed to damaging high temperatures during rehydration. Avoid rapid cooling, as it can cause shock. Once cooled, the mixture is ready for yeast addition. Proper temperature control is vital for yeast viability and fermentation performance. Always monitor the temperature closely to maintain the optimal range for rehydration and subsequent fermentation activity.

3.4 Adding Yeast to the Solution

Once the mixture has cooled to 40°C (104°F), gently add the active dried yeast. Do not stir the solution, as this can introduce oxygen prematurely; Allow the yeast to rehydrate undisturbed for 20 minutes. The yeast will absorb the nutrients from the Go-Ferm solution during this period. Ensure the ratio of yeast to Go-Ferm is 1:1.25 for optimal nutrient uptake. After rehydration, slowly add equal parts of must to the yeast slurry over 5 minutes to prevent shock. This step ensures the yeast is well-prepared for fermentation.

3.5 Acclimating the Yeast to the Must

After rehydration, slowly add equal amounts of must to the yeast slurry over 5 minutes. Monitor the temperature difference, ensuring it does not exceed 10°C (18°F) between the must and the slurry. If necessary, allow the slurry to acclimate to the must’s temperature. This step prevents shock to the yeast, which can lead to sluggish fermentation or cell death. Proper acclimation ensures the yeast adapts smoothly to the must’s conditions, promoting a healthy and vigorous fermentation process.

Dosage Guidelines

Use 1.25 parts Go-Ferm per 1 part yeast by weight. Mix in 20 times its weight in clean, 43°C (110°F) water. Proper dosage ensures optimal yeast performance.

4.1 Recommended Ratios for Yeast and Go-Ferm

The recommended ratio is 1.25 grams of Go-Ferm per 1 gram of yeast. This ensures optimal yeast rehydration and fermentation performance. Mix Go-Ferm in 20 times its weight in clean, 43°C (110°F) water. For example, 1 oz of Go-Ferm (28 grams) is sufficient for 22 grams of yeast. This ratio provides essential nutrients, supporting yeast health and preventing fermentation issues. Proper measurement is crucial, especially in high-sugar or challenging fermentation conditions. Always adjust the dosage based on the total yeast quantity for best results.

4.2 Calculating the Correct Dosage

- Calculate Go-Ferm dosage based on yeast weight: 1.25 grams of Go-Ferm per 1 gram of yeast.

- For example, 1 oz (28 grams) of Go-Ferm is enough for 22 grams of yeast.

- Mix Go-Ferm in 20 times its weight in clean, 43°C (110°F) water.

- Let the mixture cool to 40°C (104°F) before adding yeast.

- Accurate measurement ensures proper yeast nutrition and fermentation efficiency.

Tips for Optimal Use

- Ensure proper hydration by mixing Go-Ferm in clean, hot water (43°C/110°F) before cooling and adding yeast.

- Maintain optimal temperature (40°C/104°F) during rehydration to promote healthy yeast activity and fermentation efficiency.

5.1 Ensuring Proper Hydration

Proper hydration is critical for yeast health and fermentation efficiency. Mix Go-Ferm in clean, filtered water at 43°C (110°F) using a 1:20 ratio (e.g., 1 oz Go-Ferm to 18 oz water). Allow the mixture to cool to 40°C (104°F) before adding yeast. This ensures optimal nutrient absorption and prevents yeast stress. Using poor-quality water or incorrect temperatures can lead to sluggish fermentation and reduced yeast viability, emphasizing the importance of precise hydration methods for successful outcomes in winemaking and meadmaking.

5.2 Maintaining the Right Temperature

Maintaining the correct temperature is vital for yeast health and fermentation success. Heat clean water to 43°C (110°F) for mixing Go-Ferm, then cool it to 40°C (104°F) before adding yeast. Avoid temperature differences greater than 10°C (18°F) when introducing must to the yeast slurry to prevent shock. Proper temperature control ensures optimal nutrient uptake and yeast activity, promoting a healthy and efficient fermentation process. Incorrect temperatures can stress yeast, leading to fermentation issues or stalled progress, emphasizing the need for precise control during rehydration and acclimation phases.

Common Mistakes to Avoid

Over or under-dosing Go-Ferm can disrupt yeast performance and fermentation efficiency. Incorrect temperature handling during rehydration and acclimation can stress yeast, leading to poor fermentation outcomes or stalled processes.

6.1 Over or Under-Dosing

Over-dosing Go-Ferm can lead to an imbalanced nutrient profile, potentially inhibiting yeast activity. Conversely, under-dosing deprives yeast of essential nutrients, risking sluggish or incomplete fermentation. Proper measurement based on yeast quantity is crucial, as deviations can compromise fermentation efficiency and overall wine or mead quality. Always adhere to the recommended ratio of 1 part yeast to 1.25 parts Go-Ferm to ensure optimal nutrient uptake and fermentation performance. Precision in dosing is key to achieving consistent and predictable results in winemaking and meadmaking.

6.2 Incorrect Temperature Handling

Incorrect temperature handling can significantly impact yeast vitality and fermentation efficiency. Go-Ferm should be mixed with clean water heated to 110°F (43°C) to ensure proper dissolution. The mixture must then cool to 104°F (40°C) before adding yeast. If the temperature is too high, it can kill the yeast, while temperatures that are too low may prevent proper rehydration. Maintaining the correct temperature range is critical for optimal yeast health and fermentation performance. Always monitor and adjust temperatures carefully to avoid compromising the fermentation process.

Comparing Go-Ferm with Other Nutrients

Go-Ferm stands out as a specialized yeast rehydration nutrient, providing essential vitamins and minerals to enhance fermentation kinetics. Unlike other nutrients, it is specifically designed for optimal yeast health during rehydration.

7.1 Go-Ferm vs. Fermaid-O

Go-Ferm and Fermaid-O are both popular yeast nutrients but serve different purposes. Go-Ferm is specifically designed for yeast rehydration, providing essential micronutrients like vitamins and minerals to enhance yeast health and fermentation kinetics. Fermaid-O, on the other hand, is added during fermentation and contains DAP (diammonium phosphate), which supports yeast growth during the active fermentation phase. While both products optimize yeast performance, Go-Ferm focuses on the critical rehydration stage, ensuring robust yeast activity from the start, whereas Fermaid-O sustains energy and nutrient needs during fermentation.

7.2 Go-Ferm vs. Go-Ferm STEROL FLASH

Go-Ferm and Go-Ferm STEROL FLASH are both yeast rehydration nutrients but differ in composition and function. Go-Ferm provides essential vitamins, minerals, and micronutrients to enhance yeast health and fermentation efficiency. Go-Ferm STEROL FLASH includes additional sterols and fatty acids, which improve yeast survival under stress and promote aroma production. While Go-Ferm is ideal for standard fermentations, STEROL FLASH is recommended for challenging conditions, such as high sugar levels or low nutrient musts, to ensure optimal yeast performance and flavor retention.

Storage and Handling

Go-Ferm should be stored at 18°C (65°F) in a tightly sealed, dry container. Proper storage ensures stability and shelf life, maintaining its effectiveness for yeast rehydration.

8.1 Proper Storage Conditions

Go-Ferm should be stored in a cool, dry place at a temperature of 18°C (65°F). It is important to keep the container tightly sealed to prevent moisture exposure. Light exposure should also be minimized to preserve effectiveness. Once opened, ensure the container remains dry and sealed to maintain shelf life. Proper storage conditions are crucial to ensure the nutrient remains stable and effective for yeast rehydration. Avoid storing in humid or extreme temperature environments, as this can degrade the product’s quality and performance during fermentation processes.

8.2 Shelf Life and Stability

Go-Ferm has a stable shelf life when stored under recommended conditions. It remains effective if kept in a cool, dry environment at 18°C (65°F). Proper storage ensures the nutrient retains its potency and does not degrade. While it is stable over time, it is best used within a reasonable period for optimal performance. Exposure to humidity or extreme temperatures can affect its stability. Ensure the container is tightly sealed after opening to maintain its effectiveness and prevent degradation.

Go-Ferm is a vital tool for winemakers and meadmakers, enhancing yeast health and fermentation efficiency. Its proper use ensures robust, problem-free fermentations, making it a recommended addition to your process.

9.1 Summary of Key Points

Go-Ferm is a natural yeast rehydration nutrient that enhances fermentation kinetics. It provides essential micronutrients, improving yeast health and preventing fermentation issues. Proper dosage is 1.25 grams per gram of yeast, mixed with 20 times its weight in clean, 110°F (43°C) water, then cooled to 104°F (40°C) before adding yeast. Storage at 65°F (18°C) and keeping it dry ensures stability. Avoid using ammonia salts during rehydration. Go-Ferm is ideal for challenging conditions, supporting yeast survival and efficient fermentation in high-sugar or high-alcohol environments.

9.2 Final Thoughts on Using Go-Ferm

Go-Ferm is an essential tool for winemakers and meadmakers, offering a natural, effective way to enhance yeast health and fermentation efficiency. By providing critical micronutrients during rehydration, it ensures robust fermentation performance, especially in challenging conditions. Proper use of Go-Ferm as outlined in its instructions is key to preventing issues and achieving consistent, high-quality results. Its benefits make it a must-have for both novice and experienced brewers aiming for reliable and successful fermentations across various conditions.